The Impact of Ink Type on Flexographic Printing Quality

Flexographic printing, as one of the leading technologies in the packaging industry, requires the correct selection of ink. The type of ink has a direct impact on print quality, durability, and environmental sustainability. By examining water-based, solvent-based, and UV-curable inks and presenting practical recommendations, this article provides a comprehensive guide to enhancing flexographic print quality.

The Impact of Ink Type on Flexographic Printing Quality

(A Scientific and Practical Guide for the Packaging and Carton Industry)

Introduction

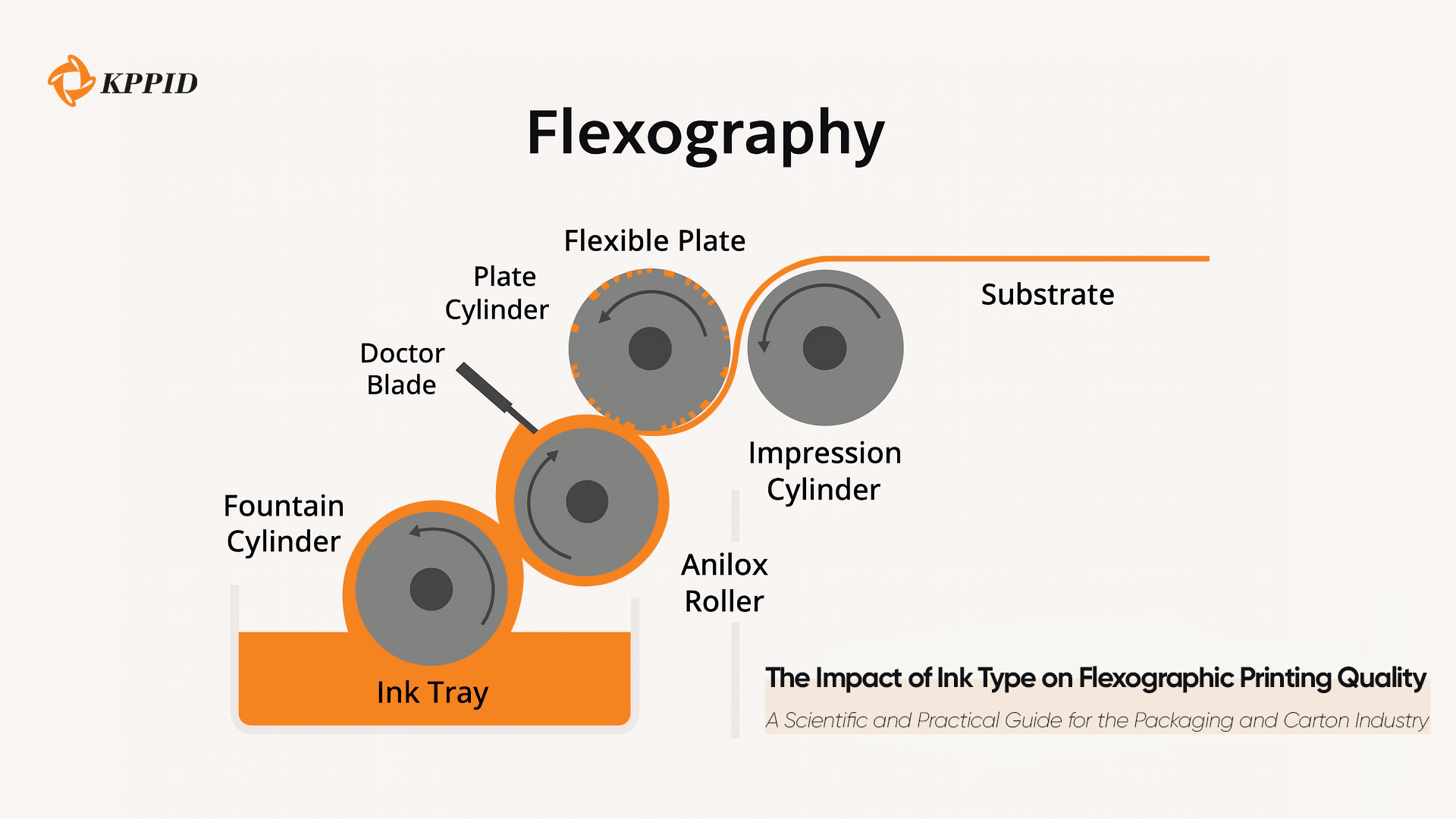

Flexographic printing (Flexographic Printing) is one of the most important printing technologies in the packaging and carton industry. Thanks to its high speed, flexibility in printing on diverse substrates, and compatibility with different types of inks, it has become the first choice for many manufacturers.

In this process, ink is transferred from the anilox roll to the photopolymer plate and then applied to the substrate. The final print quality depends on several parameters, with one of the most critical being the type of ink and its physicochemical properties. Understanding these properties and applying practical guidelines in ink usage are key to achieving accurate and long-lasting results.

Types of Flexographic Inks and Their Characteristics

1. Water-Based Inks

-

Composition: Water as solvent, organic or inorganic pigments, acrylic or alkyd resins, anti-foam agents, and dispersants.

-

Drying: Evaporation of water through hot-air dryers.

-

Advantages:

-

Very low VOC emissions (<50 g/L)

-

High safety and eco-friendly performance

-

-

Disadvantages:

-

Sensitive to humidity

-

Limited adhesion on non-polar plastic films

-

-

Main Applications: Cartons, paper, moisture-absorbent packaging.

2. Solvent-Based Inks

-

Composition: Resins and pigments dissolved in organic solvents (alcohols, esters, ketones).

-

Drying: Rapid solvent evaporation.

-

Advantages:

-

Excellent adhesion on non-polar films

-

Strong resistance to moisture and environmental conditions

-

-

Disadvantages:

-

High VOC emissions (300–600 g/L)

-

Requires industrial ventilation and strict environmental compliance

-

-

Environmental Management:

-

Compliance with EU Directive 1999/13/EC and EPA VOC regulations

-

Adoption of solvent recycling and distillation systems

-

Installation of advanced filtration and ventilation systems (ISO 14001)

-

-

Main Applications: Printing on plastic films, metallic foils, and moisture-resistant packaging.

3. UV-Curable Inks

-

Composition: UV-sensitive resins, monomers, photoinitiators, and pigments.

-

Drying: Instant polymerization under UV radiation.

-

Advantages:

-

Ultra-fast curing (milliseconds)

-

Zero VOC emissions

-

Excellent durability, gloss, and mechanical strength

-

-

Disadvantages:

-

Higher costs of inks and equipment

-

Requires safety measures when working with UV radiation

-

-

Main Applications: Premium packaging, high-detail printing, specialty labels.

Technical Comparison of Flexographic Inks

| Main Applications | Approx. VOC (g/L) | Lightfastness (Blue Wool Scale) | Drying Time | Viscosity (mPa·s) | Ink Type |

| Cartons, paper | <50 | 6–7 | Medium | 100–500 | Water-Based |

| Plastic films, foils | 300–600 | 7–8 | Fast | 200–700 | Solvent-Based |

| Premium packaging, labels | 0 | 8 | Very fast | 50–300 | UV-Curable |

Discussion

Analysis of the data and flexographic printing practice shows that:

-

Water-based inks are the best choice for absorbent substrates such as cartons and paper, though they have limited adhesion on non-polar substrates.

-

Solvent-based inks deliver superior performance on plastic films and metallic foils, especially in humid environments, despite their high VOC emissions.

-

UV-curable inks provide unmatched durability and quality but come with higher initial investment costs.

The selection of ink must be based on substrate type, durability requirements, production speed, environmental standards, and budget.

Practical Tips for Improving Flexographic Printing Quality

Before Printing:

-

Measure viscosity with a Zahn Cup or Ford Cup.

-

Control pH (for water-based inks) between 8.5 and 9.5.

-

Perform tape test to check adhesion.

During Printing:

-

Use an anilox roll with suitable cell volume.

-

Control printing pressure and machine speed.

-

Continuously stir ink to prevent pigment sedimentation.

After Printing:

-

Check color stability using a spectrophotometer.

-

Store remaining ink in sealed containers under controlled conditions.

FAQs

1. What is the best ink for flexo printing on corrugated board?

Water-based inks, due to their low VOC emissions and compatibility with board, are the best option.

2. When is UV ink a better choice than water-based ink?

In premium production where durability, gloss, and color brilliance are highly important.

3. How can flexo ink viscosity be controlled?

By using a Zahn Cup or Ford Cup and adjusting according to the ink manufacturer’s recommendations.

Conclusion

Selecting the right ink and following scientific and practical principles of flexographic printing ensure superior print quality and long-lasting results.

At Kermanshah Printing & Packaging Industries Development Co., with decades of expertise, advanced equipment, and global-standard inks, we are fully prepared to deliver the highest-quality printing for the packaging and carton industry.

🔹 Contact us today to benefit from free expert consultation.

Rest assured your products will be delivered safely and in perfect condition.

References

-

Flexographic Technical Association (FTA) – FIRST Guidelines

-

ASTM D823 – Standard Practices for Producing Films of Uniform Thickness

-

ISO 12647-6 – Process control for flexographic printing color separations

-

EU Directive 1999/13/EC – VOC Emission Limits

-

Ink World Magazine – Flexographic Printing Inks Overview

send comment

Required fields are marked *.